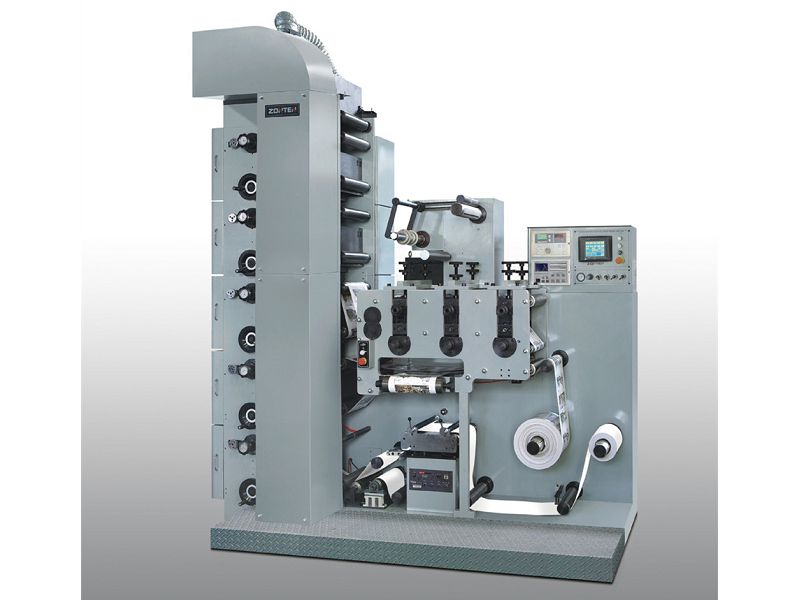

6 Colour Flexo Printing Machine

Description

The main motor from 6 colour flexo printing machine adopts imported inverter to govern a stepples speed adjustment.

The printing units are all equipped with a group of infrared dryers respectively.

Each IR dryer device of printing unit is interchangeable to UV dryer.

Feeding and rewinding are controlled through magnetic particle brake and clutch (Japanese Mitsubishi auto tension controller).

Unwinder and rewinder adopt air core holder.

Three unit rotary cut with stand-roller make, multi-cut can be processed.

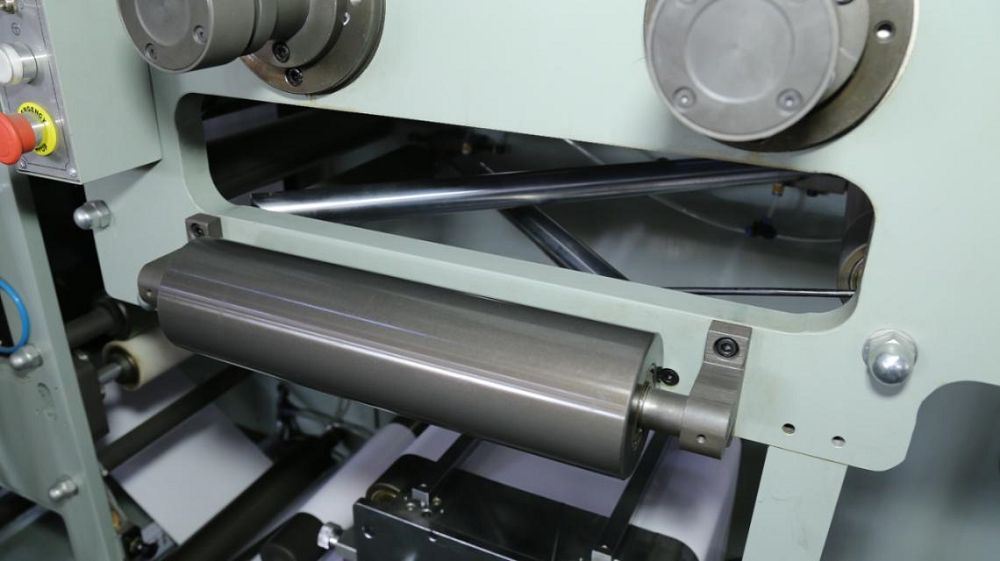

Adopt ceramic anliox roller which offers durability, wear resistance and corrosion resistance, also is more efficient on production by reducing the times of changing rollers.

The printing unit from 6 colour flexo printing machine can register in 360 degrees. Each printing unit can be independently geared and loosen to have rest of units continue to printing.

The inking roller will be automatically off impression when press stop and rotate at lower speed in order to keep the ink from being drying.

Paper unwind, printing, UV vanish laminating, rotary diecutting, waste removal and rewinding can be processed in one pass.

LRY-330/450 6 colour flexo printing machine is characterized by wide application, fast printing speed and high economic efficiency and ink pullution free. It is an ideal printing machine for the business form, tag and high end pressure sensitive label.

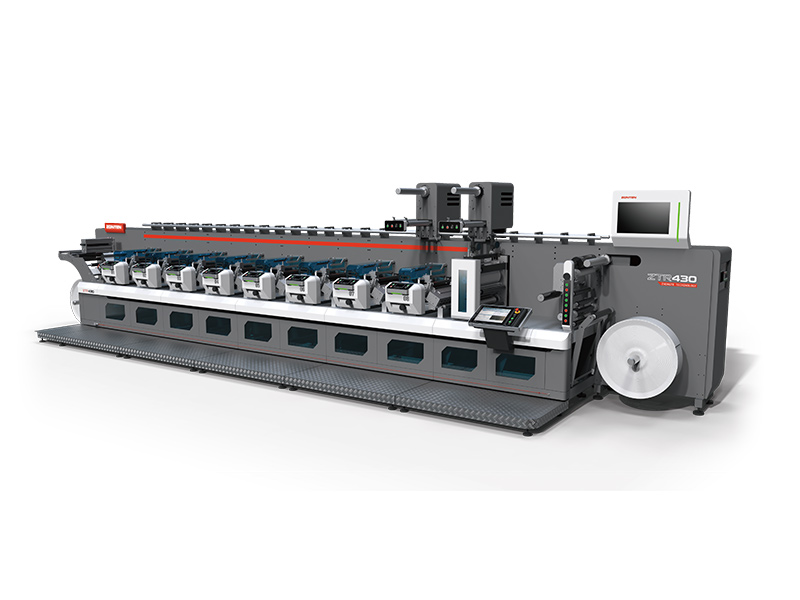

For the more marketing development , now we research 6 colour flexo printing machine in the servo motor control to increase the production

Technical Specification

| Model | LRY-320 | LRY-470 |

| Max. Web Width | 330mm | 450mm |

| Max. Printing Width | 320mm | 440mm |

| Printing Repeat | 180~380mm | 180~380mm |

| Color | 2-6 | 2-6 |

| Thickness of Substrate | 0.1~0.3mm | 0.1~0.3mm |

| Machine Speed | 10-80m/min | 10-80m/min |

| Max. Unwind Diameter | 650mm | 650mm |

| Max. Rewind Diameter | 650mm | 650mm |

| Die cutting station | 3 | 3 |

| Main motor Capacity | 2.2kw | 2.2kw |

| Main power | 3 Phases 380V/50hz | 3 Phases 380V/50hz |

| Power | ||

| Overall Dimension(LxWx H) | 2420 x1020 x2740mm | 2420 x 1020 x 2740mm |

| Machine Weight | about 2500kg/5 colors | about 3000kg/5 Colors |

More Details

Insert BST Germany brand web guide with ultrasonic edge sensor guarantee paper straight feeding

Turn bar, supporting back side printing

Cold foil device

Lamination device

Printing cylinder support thickness 1.7mm and 1.14 mm plate , support straight gear and helical gear both

The printing unit can register in 360 degree, each printing unit can be independently geared and loosen to have rest of unit dring.

BST camera and monite. All time check the ten line register