Adhesive Sticker Label Printing Machine

Description

ZTJ-330 intermittent offset press is the most advanced adhesive sticker label printing machine. This machine adopts Heidelberg SM52 series classic ink circuit structure, including 18 ink rollers and 5 water rollers, uniform ink distribution, stable ink balance and high quality printing .The effect is the customer's best choice for adhesive sticker label printing machine.

Since the first ZTJ-330 offset adhesive sticker label printing machine was put on the market in 2010, we have received unanimous praise from customers at domestic and over sea country . At present, it has established branches in Guangzhou/ Shanghai/ Beijing /Jiangsu/ Chongqing, and established offices in Southeast Asia/Korea/South America and the whole Europe to provide customers with 24-hour online sales and after-sales network

The picture above is the machine in configuration 5 offset printing unit +semi rotary hot foil + silk screen printing unit +flexo varnish unit + rotary die cutter unit which is a very popular solution for red wine label printing .Hope to give you the best customer experience through our 20 years of adhesive label printing machine manufacture experience.

Technical Specification

| Model | ZTJ-330 | ZTJ-520 |

| Max. Web Width | 330mm | 520mm |

| Max. Printing Width | 320mm | 510mm |

| Printing Repeat | 100~350mm | 150~380mm |

| Thickness of Substrate | 0.1~0.3mm | 0.1~0.35mm |

| Machine Speed | 50-180rpm(50M/min) | 50~160rpm |

| Max. Unwind Diameter | 700mm | 1000mm |

| Max. Rewind Diameter | 700mm | 1000mm |

| Pneumatic Requirement | 7kg/cm² | 10kg/cm² |

| Total Capacrty | 30kw/6 colors(Not including UV) | 60kw/6 colors(Not including UV) |

| UV Capacity | 4.8kw/color | 7kw/color |

| Power | 3 Phases 380V | 3 Phases 380V |

| Overall Dimension(LxWx H) | 9500 x1700x1600mm | 11880x2110x1600mm |

| Machine Weight | about 13 ton/6 colors | about 15 ton/6 Colors |

More Details

The weight for each printing unit is 1500kgs.

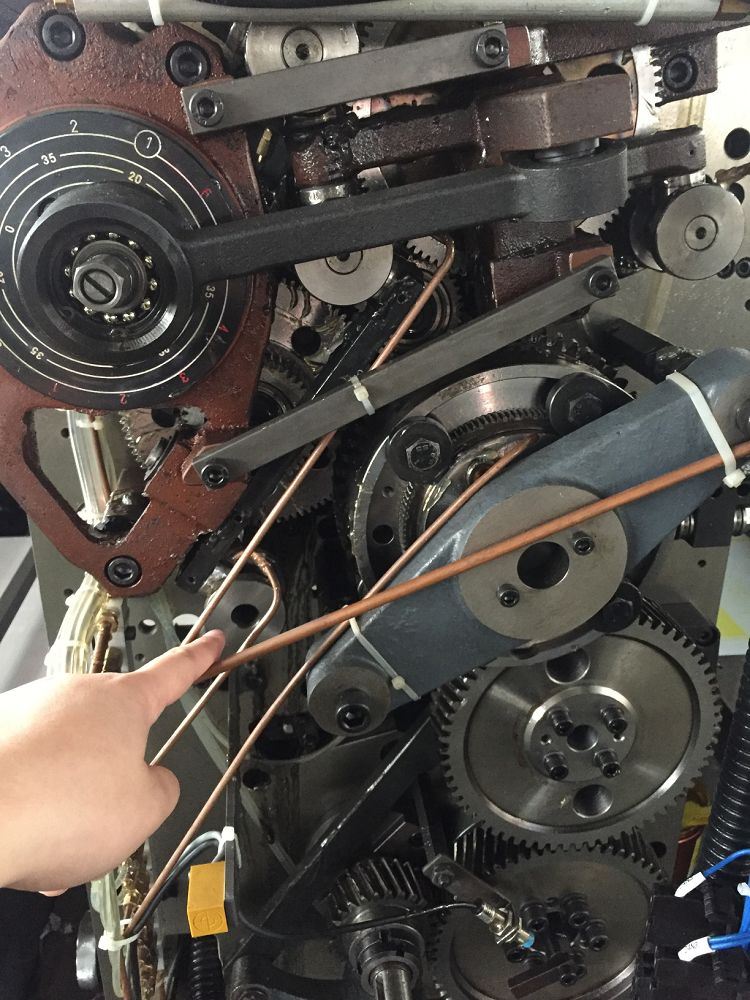

Using high-precision helical gears and fuselage panels made by Shanghai Electric's suppliers, including wall thickness 50mm, helical gear width 40mm, the maximum reduction of machine vibration and beating.

The whole machine adopts servo motor + helical gear (PS plate roller, blanket roller and embossing roller) + spur gear (uniform ink system) + stepping motor (ink fountain roller), no chain drive.

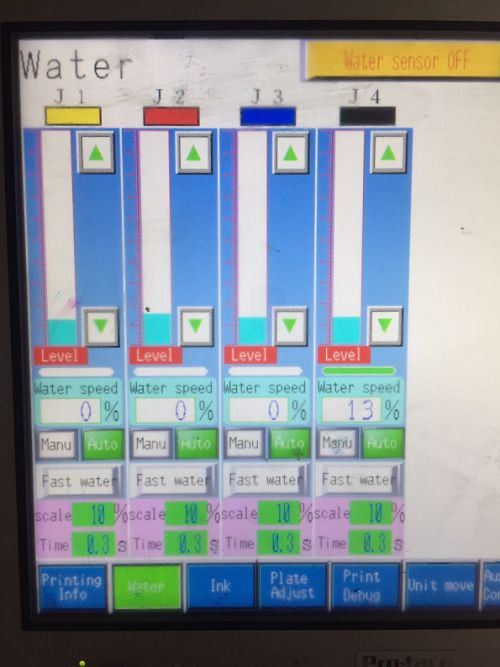

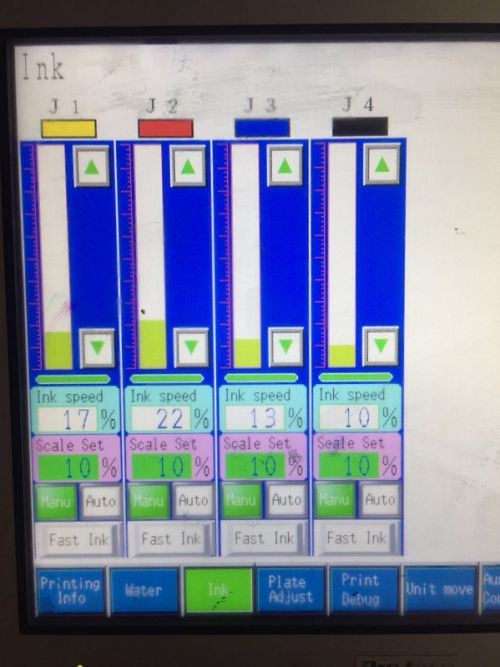

The rate of water &ink were controlled automatic ,it changed by different speed and also you can operate on touch screen.

Lineal adjustment :±5mm

Lateral adjustment :±2mm

Oblique adjustment: ± 0.12mm

Watercoress roller: Guarantee the stability of the color ,when speed up or reduce .

Europe standard electrical control box

The movement control of the unit is controlled by a servo motor to ensure the accuracy of the movement.