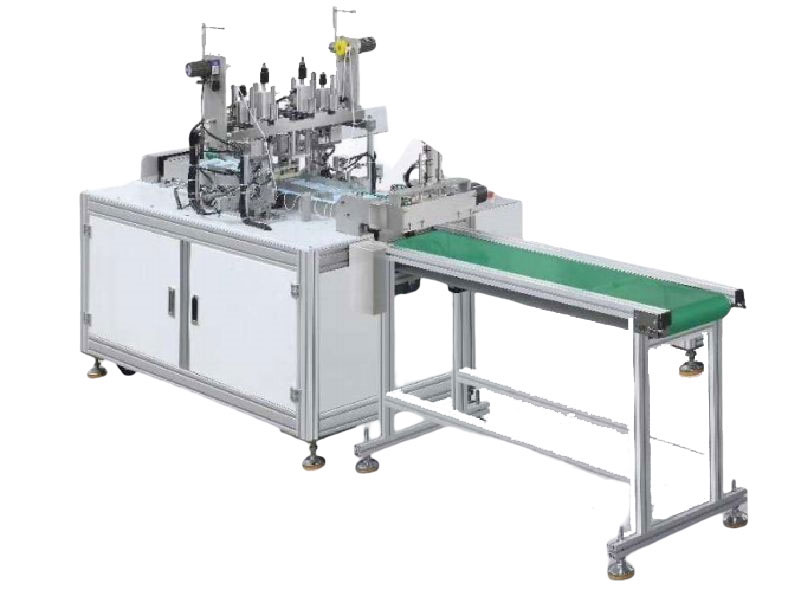

Automatic Mask Earloop Welding Machine

Description

Mask earloop welding machine is a mask processing equipment, which can be used simultaneously or offline. The function of the mask earloop welding machine is to iron the ear ropes on both sides of the mask through ultrasonic treatment. This machine adopts two 20K 2000W ultrasonic waves. The ear-smelling part (4 motors), the pull tray, and the ear rope control are all driven by servo motors, a total of 7, with precise control and low failure rate. At the same time, the mask earloop welding machine is driven by PLC, touch screen display, and count function. The whole machine does not need to be manually made by personnel. The machine can run smoothly under the touch screen control. The fastest speed can reach 100 per minute, and additional automatic release can be added. function.

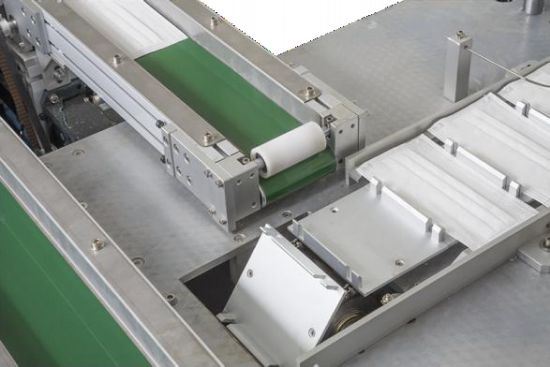

The mask earloop welding machine is equipped with a conveying platform after the ear ironing is finished. Customers can set up 5 pieces/stack or 10 pieces/stack according to their own requirements, which provides convenient services for subsequent packaging.

Technical Specification

| Modelis | |

| Machine power | 4.8kW (220V 50HZ) |

| Production speed | 60 pieces / min |

| Machine weighs | 350 kg |

| Machine frame | Aluminum-based |

| Mask level | 3-4layers |

| Min Air Press Requirement | 0.6 Mpa |

| Main unit size | 2200*1450*1500mm(length * width * height) |

| Ground load | ≤500KGMm² |

More Details

Delivery mask plate

2000w ultrasonic device

Touch screen

Full servo driver welding part

Options: folding function