China High Quality Flat Bed Die Cutting Machine Factory – Thermal Paper Roll Slitting Machine – Zhongte

China High Quality Flat Bed Die Cutting Machine Factory – Thermal Paper Roll Slitting Machine – Zhongte Detail:

Description

● FQ-900 thermal paper roll slitting machine Equipped with Panasonic PLC and Weinview touch screen, all the parameter are displayed on the monitor. You only need to setup the material roll diameter and thickness, the PLC will give a proper parameters for machine running automatically.

● FQ-900 thermal paper roll slitting machineEquipped with Auto Tension Control System for unwinding tension.

● With meter counter. Got to the setup data, the machine stops and alarms.

● FQ-900 thermal paper roll slitting machineadopts Synchronic Belt to avoid the over lap problem.

● FQ-900 thermal paper roll slitting machineadopts frequency inverter for main inverter motor driving, the speed can be displayed on the operation panel. Frequency inverter motor: 2.2Kw.

● All transmission rollers have been dynamic/static balance treated.

● Equipped with emergency switch.

● All the electric appliances on thermal paper roll slitting machine has been gained the CE certificate.

Unwinding Section

● 3” air expanding shaft.

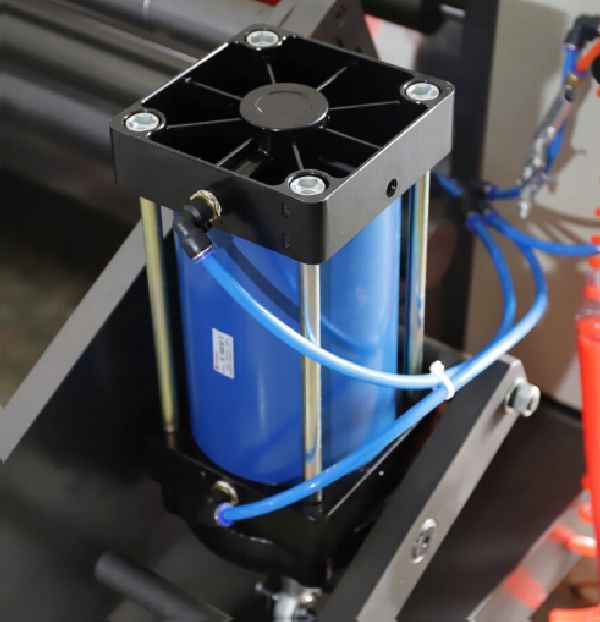

● Equipped with automatic pneumatic lift-up loading system for heavy material roll loading.

● Equipped with 10 Kg/m2 automatic braking device x 1 to material feeding tension control.

Unwinding Tension Control

● Equipped with automatic tension controller(diameter-calculating type) to gain a constant tension.

● The unwind core size, and initial unwind diameter only needs to be preset on the touch screen, the PLC controls it automatically. Easy Operation.

Auto Tucker

● It adopts Auto Tucker to tuck in the paper to cores automatically. No need paste in the tape. Easy operating and process the efficiency.

Red Line

● Set up the red line length in the touch screen. For example, 1-2 meter, when the rewinding meter reach 1 meter,it will be in the red line automatically.Also as customer requirement.

Rewinding Section

● 0.5” rewinding shafts are all available in this machine, we can also supply as request.

Trimmed Waste Edge

● Waste edge trim device is included in the slitting device. Each side of edge is used for trimming the waste edge.

● Equipped with air blow for waste material edge trimmer

Technical Specification

| Model Type | FQ-900 |

| Max. Parent Web Width | 900mm |

| Max. Parent Web Dia.: | 1000mm |

| Max. Rewinding Dia.: | 150mm |

| Max. Unwinding Speed: | 150m/min |

| Unwinding Shaft: | 3” Pneumatic Air Expanding Shaft |

| Weight: | 1000kg |

| Voltage: | 3 Phase 380V 50HZ |

| Rewinding Shaft in Diameter | 0.5”,1 inch ,Coreless(8mm) |

| Overall Dimensions: | 2050 x 1600 x 1500mm |

More Details

12 sets slitting knives

The hydraulic control feeding

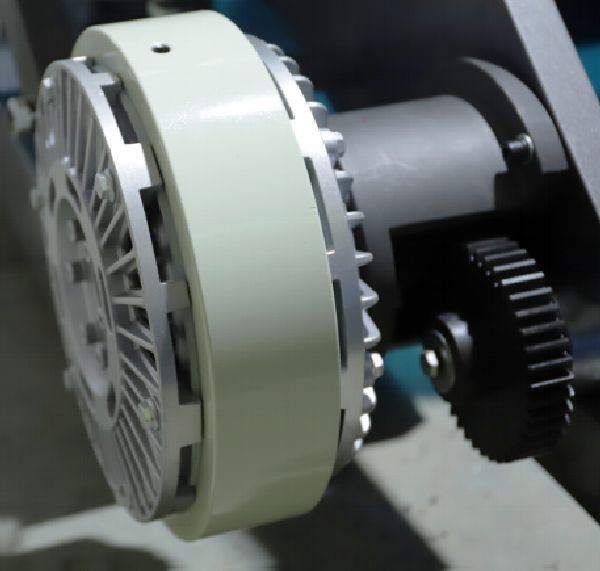

Magnetic brake & clutch control the tension

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for China High Quality Flat Bed Die Cutting Machine Factory – Thermal Paper Roll Slitting Machine – Zhongte , The product will supply to all over the world, such as: Qatar, French, USA, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We are able to also offer you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and products, please speak to us by sending us emails or call us quickly. In an effort to know our products and company extra, you may come to our factory to view it. We will generally welcome guests from all over the world to our business to create business relations with us. Please feel cost-free to speak to us for small business and we believe we'll share the best trading experience with all our merchants.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!