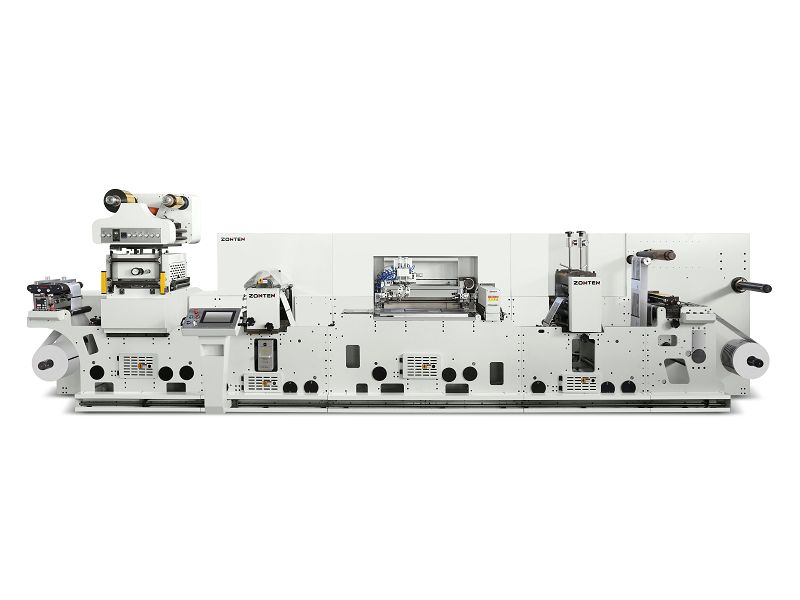

Die Cutting and Creasing Machine

Description

This die cutting and creasing machine Scope of application: processing of self-adhesive, self-adhesive labels and post-press die-cutting materials! With the advantages of labor saving and cost saving, it is the fastest die cutting machine on the market.

1. Advantages of die cutting and creasing machine:

1. Imported high-speed system centralized integrated control, using touch screen control.

2. It adopts ordinary rubber knife mold and no round knife.

3. High-speed 23000 vehicles/hour, high-speed die-cutting above 50 meters per minute, to ensure stable effect.

4. High-speed intelligent constant temperature hot stamping effect is remarkable, intelligent servo fixed length.

5. On-line waste discharge and slitting machine improves work efficiency and saves labor.

6. Single-seater and two-seater models are available.

7. Gold size 330mm (paper width direction) 260mm (jump distance direction) is suitable for most die cutting.

8. The vortex type vacuum bellows ensures constant paper tension and does not scratch the material, avoiding the use of traditional pressboard.

9. Our company has die cutting and creasing machine for trial machine!

Technical Specification

| Model | ZT-320 XYP6 |

| Max. Web width | 320mm |

| Max die cutter length | Left side 260mm , right side 330mm |

| Die cutter speed | 23000 times / minutes |

| Applicable height | 7mm-23mm |

| Applicable bottom plate thickess | 0.5mm-3mm |

| Die cutting accuracy | 0.1mm |

| Overalldimensions (L×W× H ) | 5120X1270X1890mm |

| Die cuter mold height | 20mm |

| Max. die cutter pressure | 5 Tons |

| Power | AC 380V5.5 kw |

| Machine weight | 3800kgs |

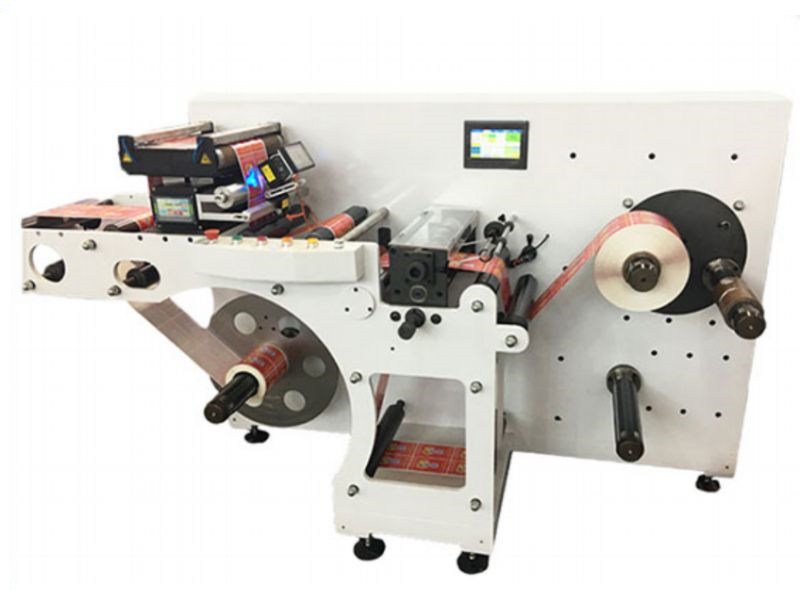

More Details

Separated unwinding with diameter 700 mm

The suction box is equipped with a vacuum return device to ensure the straight line conveyance of the paper

Left unit for hot stamping , support horizontal/ Vertical 90degree hot stamp

Right side for flat bed die cutter

Separated rewinder with diameter 700MM

Options: sheet device, acheive roll to pcs.

Touch screen with PLC controlled, all the time moniting and operating.