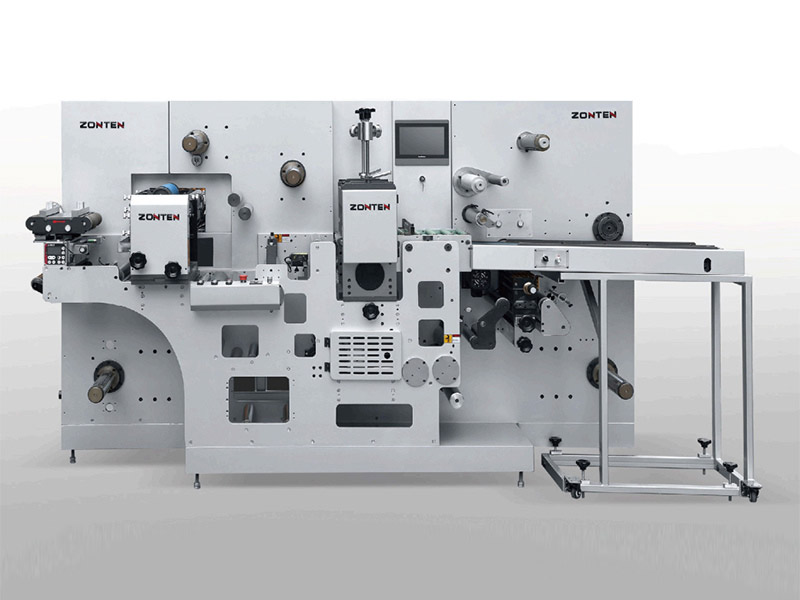

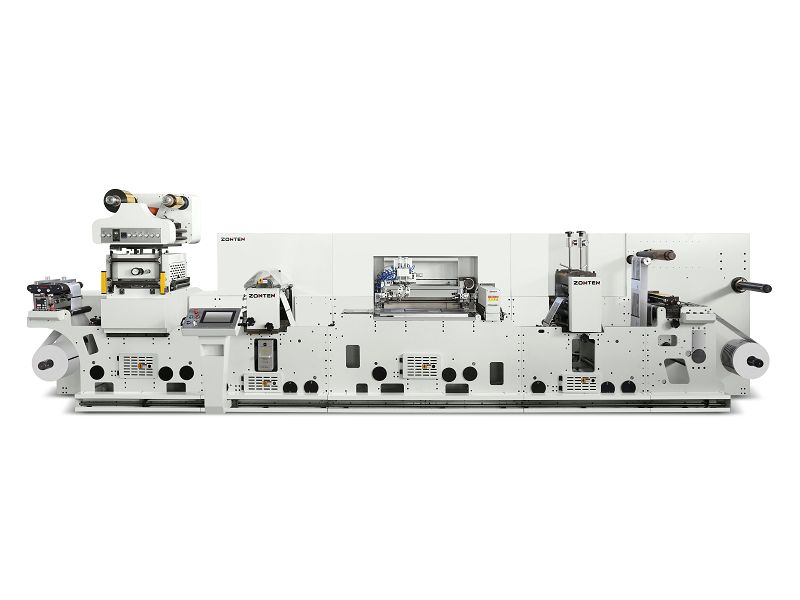

Digital Inkjet Printing Press

Description

ZONTEN DIGITAL INK JET PRINTING PRESS is equipped with 4 color ink channels as standard. It can output 4 colors at most. Each color can reach 600dpi resolution. The unique VSDT (Variable Ink Drop Technology) can freely control the ejected ink drop size. Reduce picture graininess, present more picture details, smooth color transition and high saturation, providing you with a one-stop color POD printing solution.

1. DIGITAL INK JET PRINTING PRESS adopt PrecisionCore

The ALL MEMS (Micro-Electro-Mechanical System) manufacturing process and the use of thin-film piezoelectric elements enable high-precision orifice arrangement (600dpi/2 rows) to be realized, making the print head compact, fast, high-quality, and durable.

The precise nozzle and ink path made by the unique MEMS technology make the ejected ink droplets close to a perfect circle while accurately positioning.

2. DIGITAL INK JET PRINTING PRESS Support for grey-scale

The unique VSDT (Variable Droplet Technology) can freely control the size of the ejected ink droplets, thereby reducing the graininess of the screen, presenting more screen details, smooth color transitions, and high saturation.

3. DIGITAL INK JET PRINTING PRESS have High resolution

High resolution (600dpi/color) can achieve a maximum of 4 colors output;

4. DIGITAL INK JET PRINTING PRESS have High durability

The PrecisionCore print head has excellent durability due to its high-precision processing technology. It has been optimized for many commercial and industrial printing fields to achieve high-speed output and high-quality printing

5. High durability RIP

water-based i-type inkjet system is equipped with PrintFactory RIP color processing software, which can achieve a faster, more accurate and more efficient workflow, set consistent colors, reduce ink costs, smarter work preparation, and reduce material waves. Features

Technical Specification

| Printing technology | Single PASSUV ink-jet technology, DODtechnical-grade nozzle and 4-grade grade scale | Input gas supply | 0.6-0.8 Mp |

| Resolution | DPI 600x600dpi or 600x1200dpi

DPI/rate 1200 dpi 25m/min, 2400 dpi 12. 5m/min |

Input power | Three-phase 380VAC 50/60HZ 10KW. |

| Printing speed/ min(max) | 50 m/min | Accepted file format | PDF, JPEG, BMP and other common file formats |

| Materialtype | Coated or non-coated paper, transparent or nontransparent medium | Computer hardware | Main board with HTS-PRIME Z370-A ; graphics card with HTS-GTX1070-08G. |

| Roll diameter of charging or discharging | Maximum diameter: 650 mm | Thickness of printing stock | Roll materials in 0. 01~0. 8mm. |

| Width of paper deeding | 250mm, 350mm | Image processor | RIP bundle, and synchronous printing and RIP for big data files are supported, saving RIP time. |

| Printing width | 220mm, 330mm | Drying mode | Composed of 4 sets of LEDs and a set of 5KW UV lamps and equipped with water-cooled roller toensure that the material does not deform duringfinal curing and may dry heat-deformablematerials including PVC.PET aluminum foil. |

| Ink | Cured UV printing ink | ||

| Color cell of printing | Four-color & white ink | Temperature range | 16-32°C |

| Machine size (LXWXH) | 4510mmx2410mmx 2680 mm | Storage temparure for ink | 16-32°C |

| Machine weigh | 3.2 tuns approimately | Humidty range | 40-60% |

More Details

Web guide control

Feeding roller

Inking control unit ,support max 6 color print

UV inks

LED UV dryer

Italy brand mark sensor

Control panel