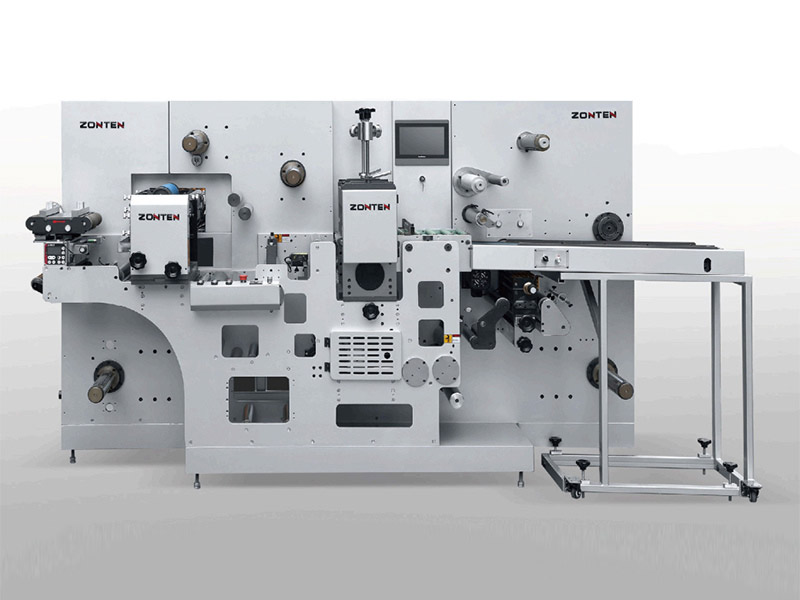

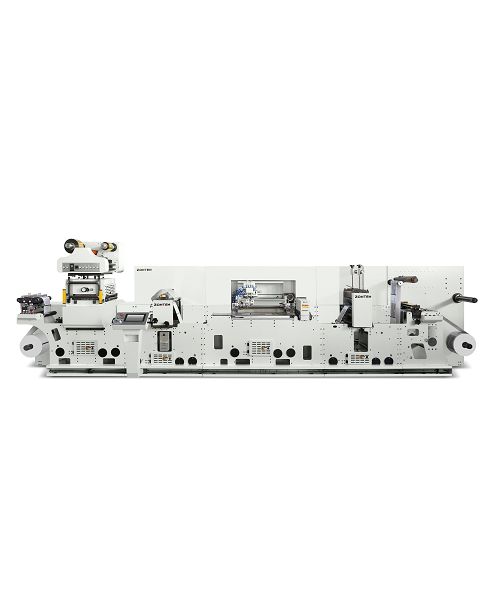

Flat Hot Stamping/ Die Cutter Label Finishing Machine

Description

Due to the shortcomings of digital printing machines, they can only perform printing functions. The demand for combined label finishing machines has increased sharply. As a leader in combined equipment in the printing press field, ZONTEN has successfully developed label finishing machines in response to the requirements of users. .

In addition to the standard die-cutting function, the current ZONTEN Dragon -320 label finishing machine can also be equipped with screen printing, flat ironing, round ironing, polishing, and cold ironing. Modular function setting allows each function to be matched at will. At present, the combined label printing machine is well received by European customers, and several units have been installed in Spain, Italy and other places.

If you are interested in label finishing machine, please contact us for more information, thank you.

Technical Specification

| Modelis | Dragon -330 |

| Max effective paper width | 330MM |

| Max unwinding dia | 700mm |

| Max rewindinng dia | 700mm |

| Registration | Sensor |

| Die cutting &hot stamp area | 320*350mm |

| Die cutting speed | 400rpm/min

120M/minutes |

| Air supply | 0.4-0.6pa |

| Dimension | 5650*1510*1820MM |

| Weight | 8000 kgs |

More Details

Hot stamping unit:

1. Horizontal/vertical 90°rotating and adjustable stamping

2 The sliding axis controls the material, and multiple rolls of material can be stamping at the same time

Servo driver controlled Sheet device , PLC control the sheet length

Semi rotary flexo unit : full servo driver controlled , can do semi rotary &rotary two method running, 152Z printing cylinder equipped, 1.7mm /1,14 plate thickness use, o,38 mm adhesive tapes.

Slitting device with ten round knife euqipped. minmimum slit width 17mm.

Silk screen unit.

Semi rotary & rotary die cutter device , Magnetic cylinder in 152Z

All imported Main electrcia parts including panasonic servo motor & driver, Trio UK PLC and etc.