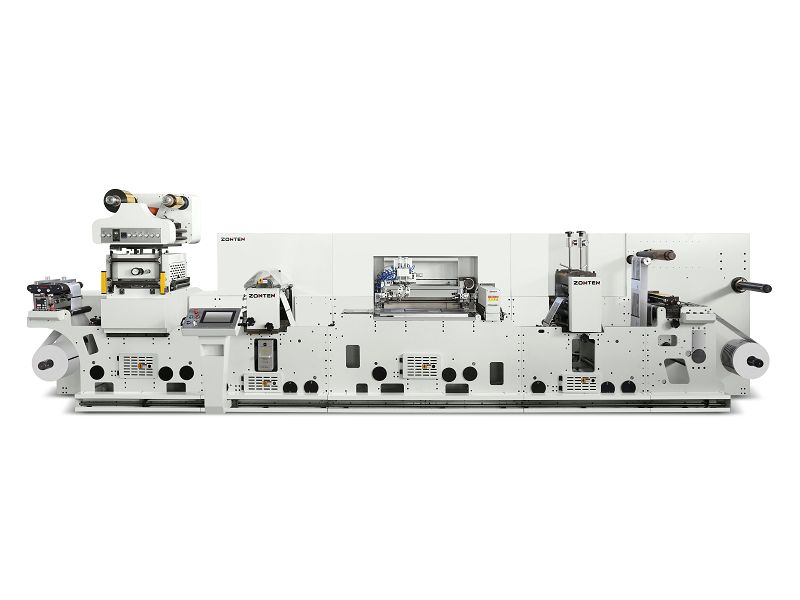

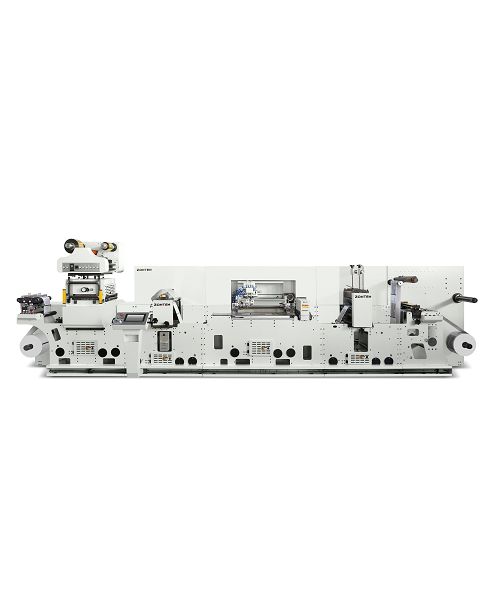

High Speed Die Cutting Machine

Description

ZONTEN Machinery independently researched and developed patented products. With the label market price moving towards the era of meager profit and higher and higher labor costs, the flat bed high speed die cutting machine was developed. This equipment adopts a floating paper feeding system with a maximum speed of 120m/min (400 times/min). Except for the intermittent movement of the paper in the die-cutting part, the rest of the paper is fed at a constant speed.

At the same time, the Dragon flat bed high speed die cutting machine is also equipped with a full servo driver controlled hot stamping unit, and the stamping heating system is an electric heating system. Servo-type intermittent foil tape rewinding and unwinding can ensure high-speed stability of 120 m/min, adjustable size and spacing, and support 90-degree rapid rotation. The foil tape rewinding and unwinding adopts a pneumatic slip shaft, which can use multiple foil tapes with different roll diameters at the same time, and can hold a maximum of 3000 meters of foil tape, which greatly improves efficiency.More and more customers use flat bed high speed die cutting machine to replace the previous low speed machine.

Technical Specification

| Modelis | Dragon -330 |

| Max effective paper width | 330MM |

| Max unwinding dia | 700mm |

| Max rewindinng dia | 700mm |

| Registration | Sensor |

| Die cutting &hot stamp area | 320*350mm |

| Die cutting speed | 400rpm/min

120M/minutes |

| Air supply | 0.4-0.6pa |

| Dimension | 5650*1510*1820MM |

| Weight | 8000 kgs |

More Details

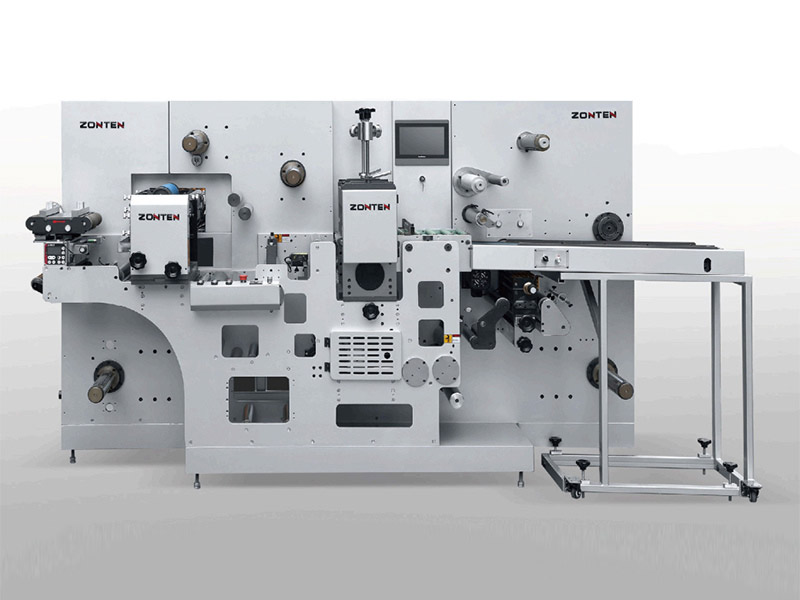

BST webgui: unwinder with closed - loop tension control, electronic web guide with ultrasonic edge guide sensor

Slitting device with ten round knife euqipped. minmimum slit width 17mm.

Hot stamping unit:

1. Horizontal/vertical 90°rotating and adjustable stamping

2. The sliding axis controls the material, and multiple rolls of material can be stamping at the same time

Snowable waste collection: very good solution for un normal shape label after die cutter, won’t brake when do waste collection process

Italy brand colful tracking sensor to moniting register ten lins