Intermittent Offset Label Presses

Description

ZTJ-330 offset adhesive sticker labelling machine, as ZONTEN’s flagship printing machine, is currently occupying the European market rapidly.

Due to the shrinking market economy and the unique advantages of the offset adhesive sticker labelling machine in red wine labels, more and more European buyers are watching the ZONTEN ZTJ-330 offset adhesive sticker labelling machine. Currently, ZONTEN has a European headquarters in Spain, and There are direct agents in Spain/Italy/France/Germany and other countries.

In addition to the traditional standard 5-color/6-color offset adhesive sticker labelling machine, European customers prefer multi-function printers including online hot stamping/screening/cold stamping/coating functions. So far, ZONTEN has installed more than 50 units in Europe Equipment, if you have any needs in this regard, please contact us.

Technical Specification

| Model | ZTJ-330 | ZTJ-520 |

| Max. Web Width | 330mm | 520mm |

| Max. Printing Width | 320mm | 510mm |

| Printing Repeat | 100~350mm | 150~380mm |

| Thickness of Substrate | 0.1~0.3mm | 0.1~0.35mm |

| Machine Speed | 50-180rpm(50M/min) | 50~160rpm |

| Max. Unwind Diameter | 700mm | 1000mm |

| Max. Rewind Diameter | 700mm | 1000mm |

| Pneumatic Requirement | 7kg/cm² | 10kg/cm² |

| Total Capacrty | 30kw/6 colors(Not including UV) | 60kw/6 colors(Not including UV) |

| UV Capacity | 4.8kw/color | 7kw/color |

| Power | 3 Phases 380V | 3 Phases 380V |

| Overall Dimension(LxWx H) | 9500 x1700x1600mm | 11880x2110x1600mm |

| Machine Weight | about 13 ton/6 colors | about 15 ton/6 Colors |

Features

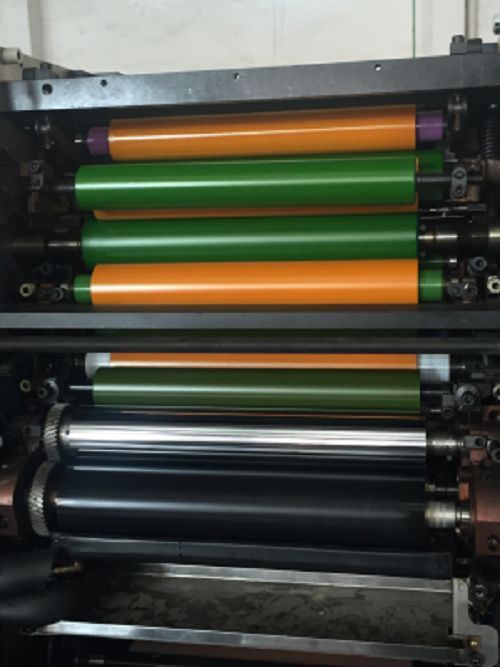

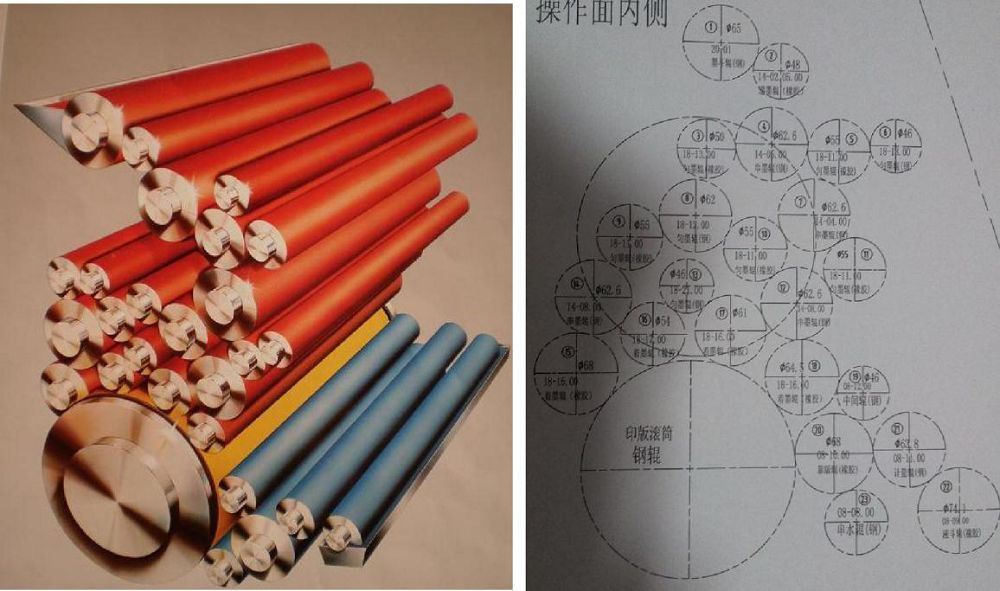

1. Using the most advance inking system with 23 ink roller to guantee printing quality

2. Four large diameter inking roller for stebility ink transfer

3. Five pieces water roller with alcohol damping system can quickly acheive water -ink balance and less water quirment

4. Bigger diamater ink roller from 46 to74.1mm

5. Double side ink route

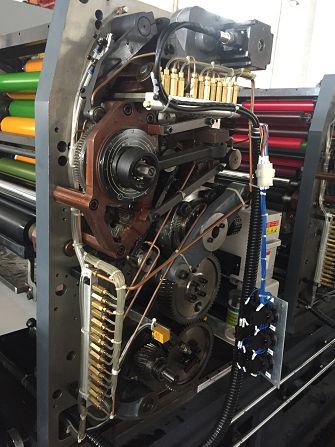

6. Automatic ink roller washing system

More Details

The weight for each printing unit is 1500kgs.

Using high-precision helical gears and fuselage panels made by Shanghai Electric's suppliers, including wall thickness 50mm, helical gear width 40mm, the maximum reduction of machine vibration and beating.

The whole machine adopts servo motor + helical gear (PS plate roller, blanket roller and embossing roller) + spur gear (uniform ink system) + stepping motor (ink fountain roller), no chain drive.

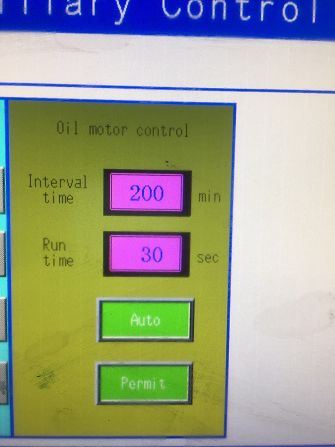

Automatic lubrication : Adopt drop lubrication ,every oil is one-time use;each lubrication point, the required amount of oil precise control, filling time to set the precise, to ensure that the equipment operating accuracy and life.