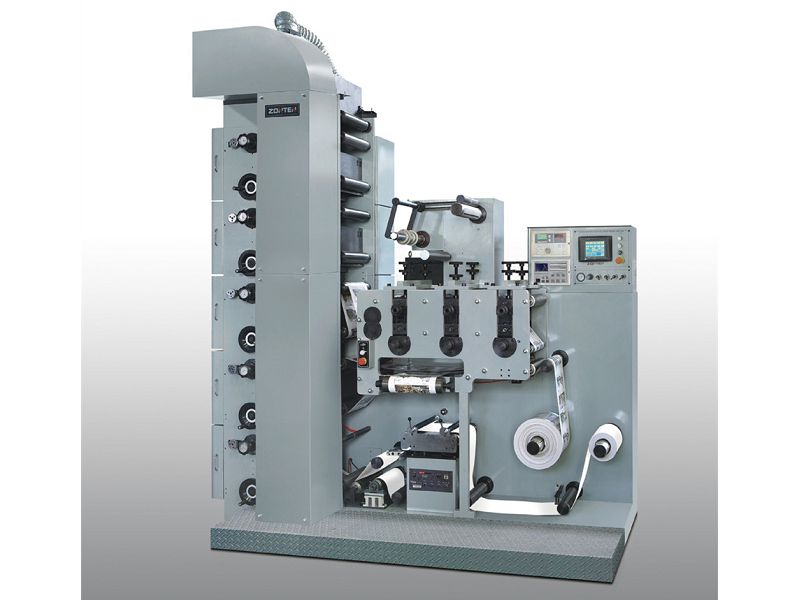

Multi-function Combination Web Printing Press

Description

The SMART-420 web offset machine has been well received by customers since it was displayed in Guangzhou Sinolabel in March 2018. Currently, more than 20 sets have been installed in China, and many potential customers are in the process of sample testing.

As the most high-end combined printing machine, SMART-420 web offset machine adopts unit type module combination method, which can be used for 4-12 color printing. Each color group can choose any printing method among offset printing, flexo printing, silk printing and cold stamping.

The whole machine adopts shaftless transmission, equipped with automatic registration system and pre-registration system to ensure accurate registration at high speed (150m/min), optional secondary printing function and front and back printing function, the registration is accurate and stable. It is an ideal equipment for printing medium and high-end daily chemical products, wine labels, medicine labels, packaging boxes, self-adhesive labels, etc.

If you are interested in SMART-420 web offset machine, please feel free to contact us.

Technical Specification

| Machine speed

Maximum print repeat length |

150M/ min 4-12color

635mm |

| Minimum print repeat length

Maximum paper width |

469.9mm

420mm |

| Minimum paper width

Maximum print width |

200mm (paper)、 300mm (film)

410mm |

| Substrate thickness

Unwinding the largest diameter |

0.04 -0.35mm

1000mm / 350Kg |

| Winding the largest diameter

Cold maximum income, unwinding diameter |

1000mm / 350Kg

600mm / 40Kg |

| Offset printing plate thickness

Flexographic printing plate thickness |

0.3mm

1.14mm |

| Blanket thickness

Servo motor power |

1.95mm

16.2kw |

| UV power

voltage |

6kw*6

3p 380V±10% |

| Control voltage

frequency |

220V

50Hz |

| Dimensions

Machine net weight |

16000×2400×2280/7color

Offset/flexo 2270Kg |

| Machine net weight

Machine net weight Machine net weight |

unwinding 1400Kg

Die cutter&waste collection 1350Kg rewinder 920Kg |

More Details

Moveable turn bar unit , support back side printing

Automatic register system

The register accuracy is 0.05mm ,and can be automatic adjust in axial direction and radial direction .it automatically to identify register error , adjust to correct from time to time to guarantee steady register

Combinated Flexo unit. Adopt the classic petal structure, the plate cylinder is easy to replace, suitable for large-solid printing and coating.

Shaftless printing cylinder and blanket cylinder : using magnalium printing cylinder and blanket cylinder with double -pinch clamping technology for easily changing printing area nad printing method , convenience operator and low maintanance cost.

Flexo plate mounting machine and offset plate bending machine. It’s a Free supporting parts when customer buy the machine

Center control screen:

The machine parameters can be adjusted and shored at every work order by digital handles with also contain the machine best state in the printing time .the data cam isedd to setting machine state when the work order is stored and recalled , and achieve the control to whole machine include the basic function turning on ,turning off , speed adjustment , counting etc ....