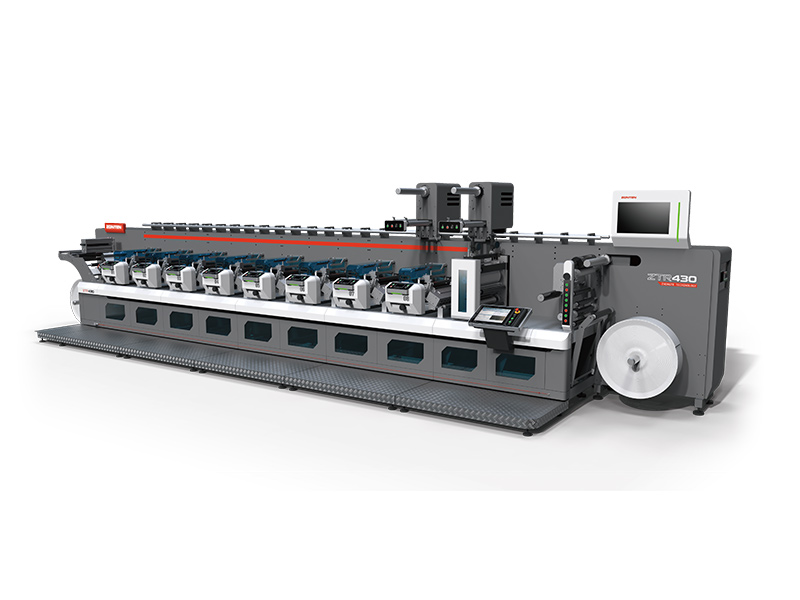

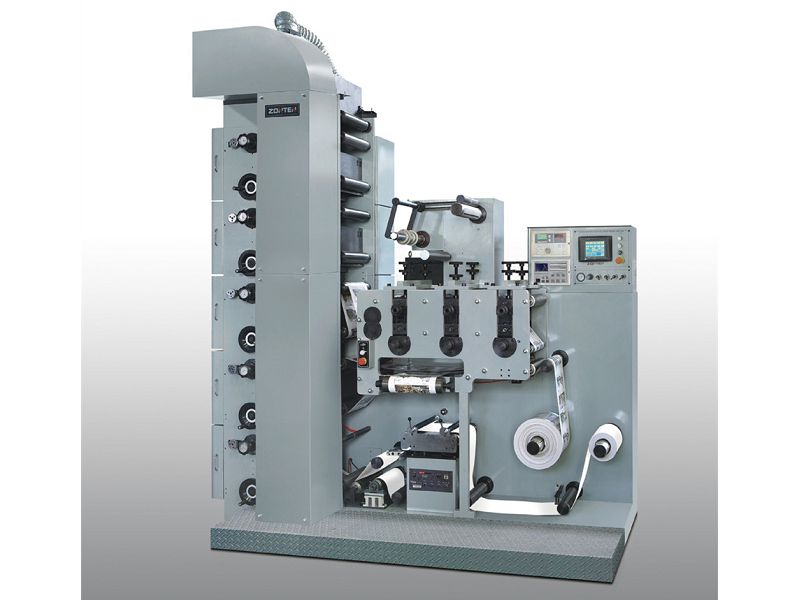

Multicolor Offset Printing Machine

Description

SMART-420/560/680 multicolor offset printing machine is suitable for the printing of carton cigarette packs, especially to solve the problem of excessive investment in single-sheet printing machines.

Compared with a single-sheet printing machine, each function must be equipped with an independent device.

SMART-420/560/680 multicolor offset printing machine has the advantages of multi-functional combination, which can be printed-cold foil-glazing-die cutting-screen-embossing on the same equipment, providing customers with productivity while reducing labor Cost and equipment cost.

SMART-420/560/680 multicolor offset printing machine, as a new generation of high-performance printing machine, is bound to subvert the industry pattern and provide customers with more options for the improvement of processes.

If you are interested in SMART-420/560/680 multicolor offset printing machine, please feel free to keep in touch with us.

Technical Specification

| Machine speed

Maximum print repeat length |

150M/ min 4-12color

635mm |

| Minimum print repeat length

Maximum paper width |

469.9mm

420mm |

| Minimum paper width

Maximum print width |

200mm (paper)、 300mm (film)

410mm |

| Substrate thickness

Unwinding the largest diameter |

0.04 -0.35mm

1000mm / 350Kg |

| Winding the largest diameter

Cold maximum income, unwinding diameter |

1000mm / 350Kg

600mm / 40Kg |

| Offset printing plate thickness

Flexographic printing plate thickness |

0.3mm

1.14mm |

| Blanket thickness

Servo motor power |

1.95mm

16.2kw |

| UV power

voltage |

6kw*6

3p 380V±10% |

| Control voltage

frequency |

220V

50Hz |

| Dimensions

Machine net weight |

16000×2400×2280/7color

Offset/flexo 2270Kg |

| Machine net weight

Machine net weight Machine net weight |

unwinding 1400Kg

Die cutter&waste collection 1350Kg rewinder 920Kg |

More Details

Basic 2 sets die cutting unit, support front and back side die cutter

Flexo plate mounting machine and offset plate bending machine. It’s a Free supporting parts when customer buy the machine

Center control screen:

The machine parameters can be adjusted and shored at every work order by digital handles with also contain the machine best state in the printing time .the data cam isedd to setting machine state when the work order is stored and recalled , and achieve the control to whole machine include the basic function turning on ,turning off , speed adjustment , counting etc ....

BST camera: Real-time monitoring of registration

12. Europe standard electrical box with CE safety certication

All the inking roller adpot Brottcher Germany to ensure high printing quality

Automatic inking control system accuary control the quantity of ink all the time

Ink remover guarantee the ink always flowing.

Upon side is two corona treatment to deal both side of material before printing, especially for film material to increase the surface to lock the ink.

Down side is the web cleaner to keep material without dust before printing .