N95 Automatic Face Mask Making Machine

Description

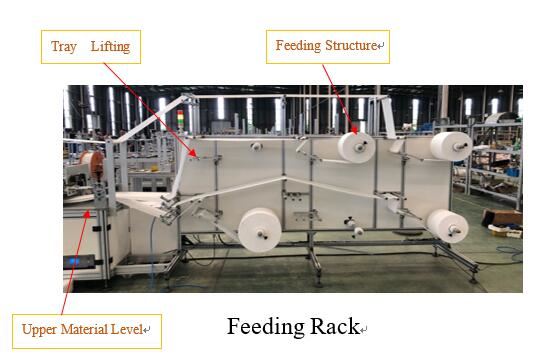

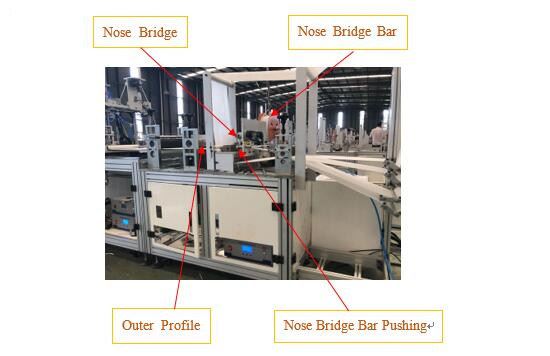

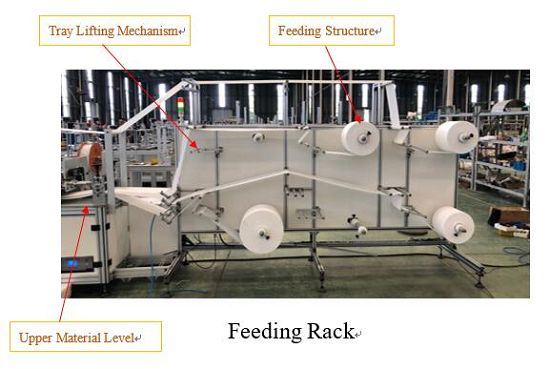

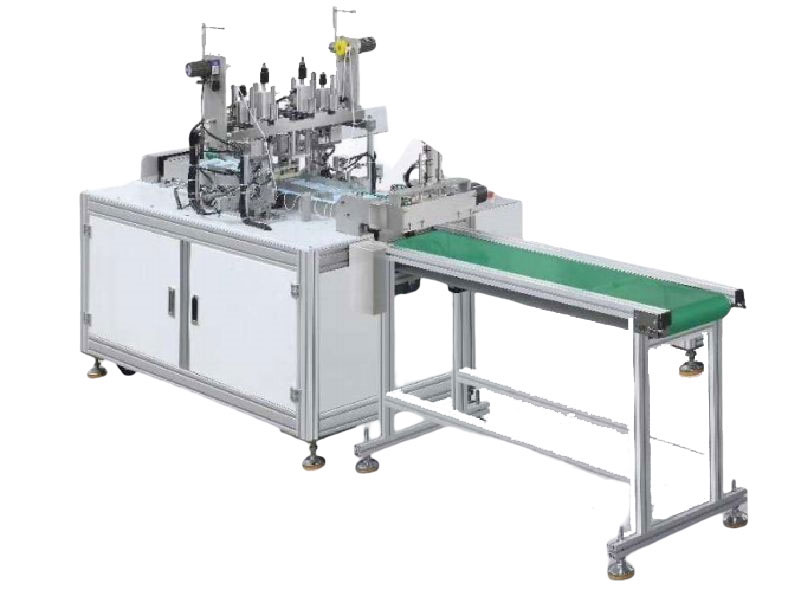

N95 mask making machine are generally composed of 3-6 layers of cloth( see the picture below for details).This N95 mask making machine can make up to 6 layers of masks. The whole roll of cloth is put in and then compounded by a roller, the cloth is mechanically folded, pulled and unrolled by the whole roll of the nose bridge bar, and then cut to a fixed length and imported to the edge of the bag, both sides are welded to the seal by ultrasonic, then through the ultrasonic side sealing, Through the cutting knife cutting molding, Joint forming with welding of left and right ear-loops, type printing is optional, the product can be sold directly after the subsequent integral molding for disinfection; Automatic counting, can effectively control the production efficiency and production progress, frequency conversion control, can adjust the running speed of theN95 mask making machine according to the actual needs, high degree of automation of the equipment, low requirements for the operation of staff, only feeding and finishing products can be, modular, user-friendly design and maintenance convenience.

Now days , N95 mask making machine is exported a lot to the European market and South American market.

Technical Specification

| Dimension | 9000mm(L)x 1500mm(W)x 2100mm(H) |

| Driving method | Servo motor and stepping motor |

| Electric control method | Computer PLC program control |

| Control panel | HMI (Touch Screen) and Button |

| Energy consumption | Three-phase 380V,50 HZ (The rated power is about 15kw) |

| Air pressure | · 0.5~0.7 Mpa, The usage flow is about 300L/min |

| Applicable process | 3-6 layers medical and ordinary masks |

| Product specification | Standard:218 x 130mm (As shown in the figure below) |

| Capacity | About 35~50 pcs/min |

| Qualification rate | Above 99% |

| Weight | ≤2500 kg, ground bearing ≥500 kg/m3 |

More Details