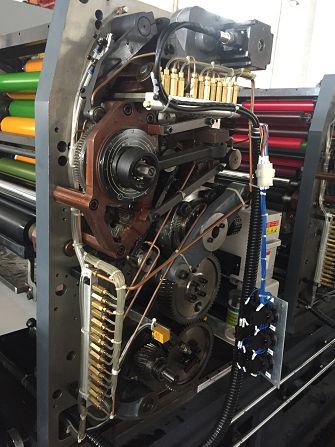

Narrow Web Label Printing Machine

Description

As the main product of narrow web label printing machine, ZTJ-330 offset printing presses occupy a large market share with high-end printing quality and stable printing speed. At present, the annual domestic installation volume exceeds 150 units and the overseas installation exceeds 50 units.

Why ZTJ-330 narrow web label printing machine opportunity is so popular, mainly in the following aspects:

1. Stable body structure. The base is a cast iron structure, the wall thickness of the fuselage is 50MM, taking 6 colors as an example, the total weight of the machine is 12 tons, which ensures stable color registration in high-speed printing.

2. The most advanced fiber optic module control system. The British TRIO controller is used with the Japanese PANASONIC servo motor to ensure the stable and efficient operation of the machine's motion module. European standard electric cabinet box makes every customer trustworthy

3. High-quality printing quality. As the roll-to-roll printing machine of Heidelberg SM52, the stable ink system is extended to make the dot reduction rate more delicate and clear.

4. The auxiliary materials are more economical. As an intermittent operation equipment, it can print for any length within 350MM plate length without changing the plate cylinder. PS plates are cheaper and consume less ink.

If you have any requirements for narrow web label printing machine, please contact us.

Technical Specification

| Model | ZTJ-330 | ZTJ-520 |

| Max. Web Width | 330mm | 520mm |

| Max. Printing Width | 320mm | 510mm |

| Printing Repeat | 100~350mm | 150~380mm |

| Thickness of Substrate | 0.1~0.3mm | 0.1~0.35mm |

| Machine Speed | 50-180rpm(50M/min) | 50~160rpm |

| Max. Unwind Diameter | 700mm | 1000mm |

| Max. Rewind Diameter | 700mm | 1000mm |

| Pneumatic Requirement | 7kg/cm² | 10kg/cm² |

| Total Capacrty | 30kw/6 colors(Not including UV) | 60kw/6 colors(Not including UV) |

| UV Capacity | 4.8kw/color | 7kw/color |

| Power | 3 Phases 380V | 3 Phases 380V |

| Overall Dimension(LxWx H) | 9500 x1700x1600mm | 11880x2110x1600mm |

| Machine Weight | about 13 ton/6 colors | about 15 ton/6 Colors |

More Details

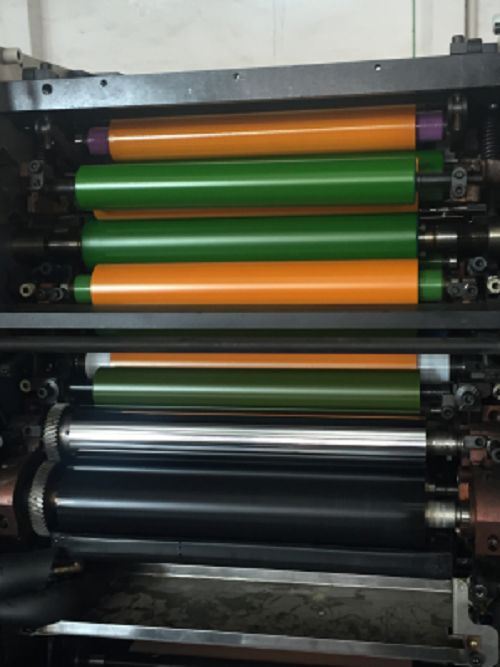

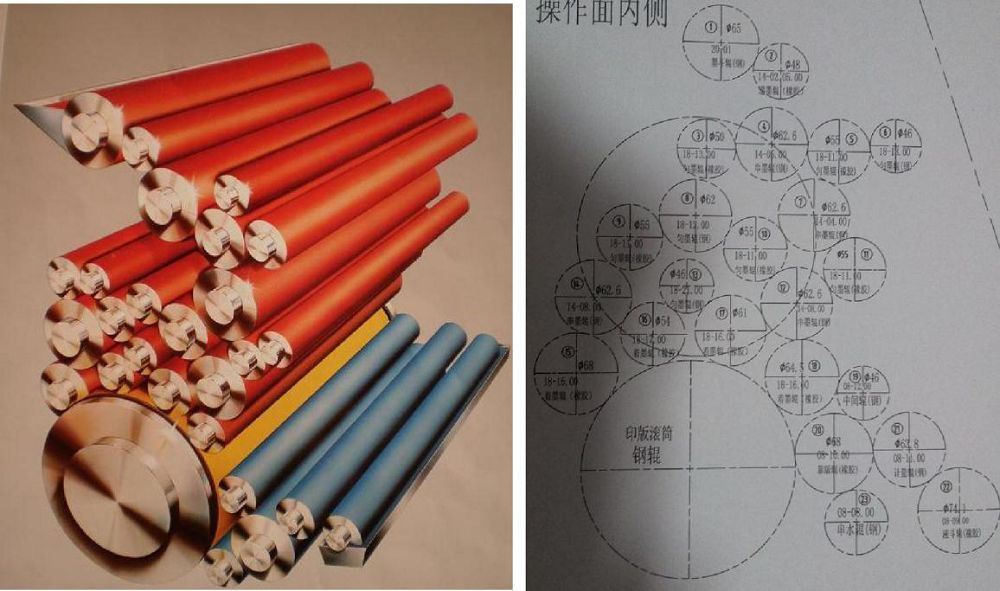

1. Using the most advance inking system with 23 ink roller to guantee printing quality

2. Four large diameter inking roller for stebility ink transfer

3. Five pieces water roller with alcohol damping system can quickly acheive water -ink balance and less water quirment

4. Bigger diamater ink roller from 46 to74.1mm

5. Double side ink route

6. Automatic ink roller washing system

The rate of water &ink were controlled automatic ,it changed by different speed and also you can operate on touch screen.

Flexo uv varnish unit

Rotary die cutter unit

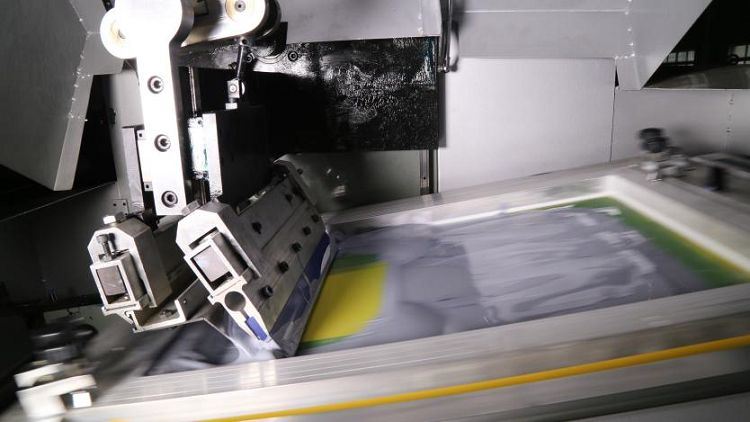

Silk screen unit

Cold foil unit

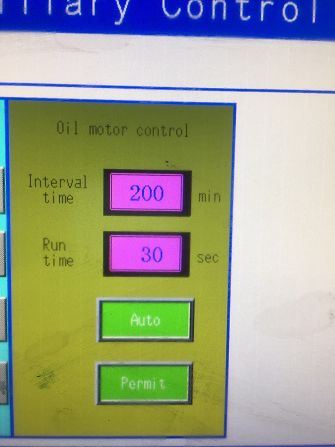

Automatic lubrication: Adopt drop lubrication ,every oil is one-time use;each lubrication point, the required amount of oil precise control, filling time to set the precise, to ensure that the equipment operating accuracy and life.