Offset Label Printing Machine

Description

In the traditional printing field, customers like to compare the offset label printing machine with the flexo printing machine from the printing speed / quality /Cost performance and so one. However, each offset label printing machine and flexo machine has it’s own advantage and even can cooperate together.

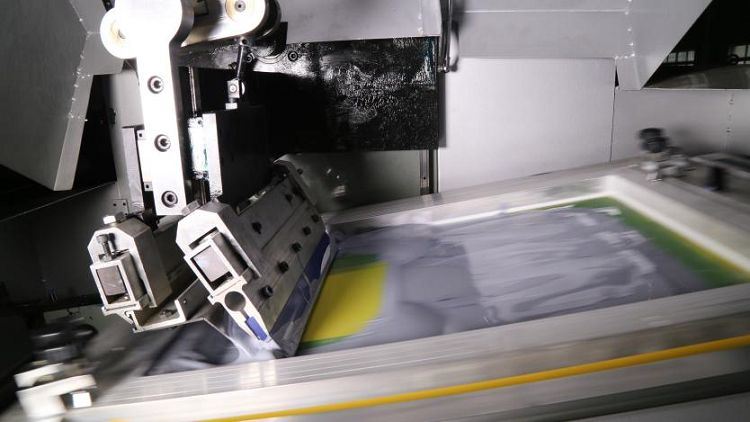

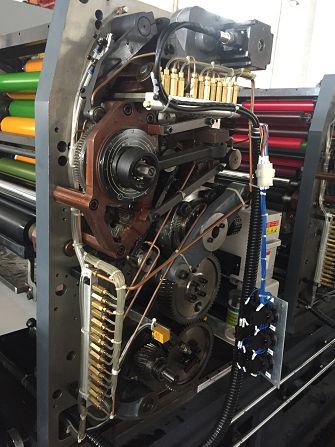

About ZTJ-330 offset label printing machine , it’s the semirotary running ,which no need to printing cylinder in any size within 350mm .This is a very big advantage for customers shortrun job because no need to cost on printing cylinder any more . Meanwhile , the inktransfer from offset label printing machine is by 23 pcs inking roller moving , it can control the ink quantity automatic by computer ,the customer also save cost from anloix roller if compared with flexo machine.

For offset label prinnting machine , the most important thing is water - ink balance , Zonten brand ZTJ-330 adpot the Classic Heidelberg Speed Master 52 construction which can ensure stable of the printing quality ,and help ZONTEN get large market share in China and oversea market.

Technical Specification

| Model | ZTJ-330 | ZTJ-520 |

| Max. Web Width | 330mm | 520mm |

| Max. Printing Width | 320mm | 510mm |

| Printing Repeat | 100~350mm | 150~380mm |

| Thickness of Substrate | 0.1~0.3mm | 0.1~0.35mm |

| Machine Speed | 50-180rpm(50M/min) | 50~160rpm |

| Max. Unwind Diameter | 700mm | 1000mm |

| Max. Rewind Diameter | 700mm | 1000mm |

| Pneumatic Requirement | 7kg/cm² | 10kg/cm² |

| Total Capacrty | 30kw/6 colors(Not including UV) | 60kw/6 colors(Not including UV) |

| UV Capacity | 4.8kw/color | 7kw/color |

| Power | 3 Phases 380V | 3 Phases 380V |

| Overall Dimension(LxWx H) | 9500 x1700x1600mm | 11880x2110x1600mm |

| Machine Weight | about 13 ton/6 colors | about 15 ton/6 Colors |

More Details

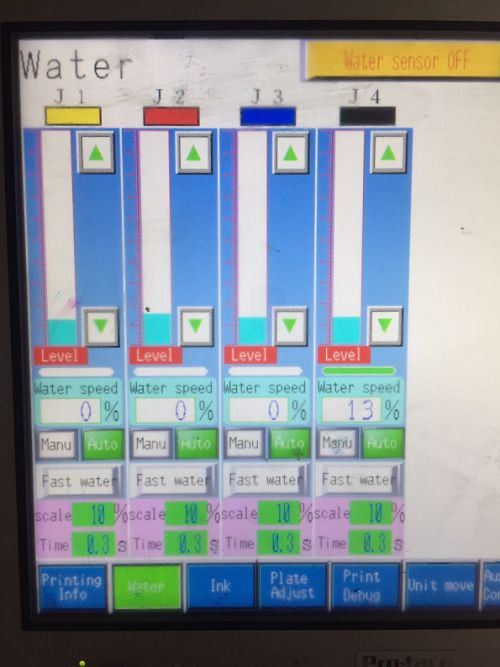

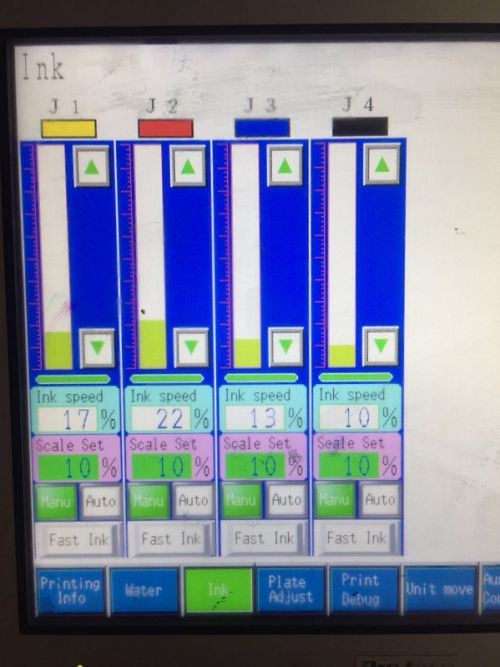

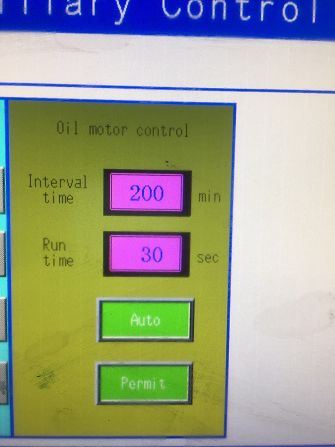

The rate of water &ink were controlled automatic ,it changed by different speed and also you can operate on touch screen.

Lineal adjustment :±5mm

Lateral adjustment :±2mm

Oblique adjustment: ± 0.12mm

Flexo uv varnish unit

Rotary die cutter unit

Silk screen unit

Cold foil unit

Watercoress roller : Guarantee the stability of the color ,when speed up or reduce .

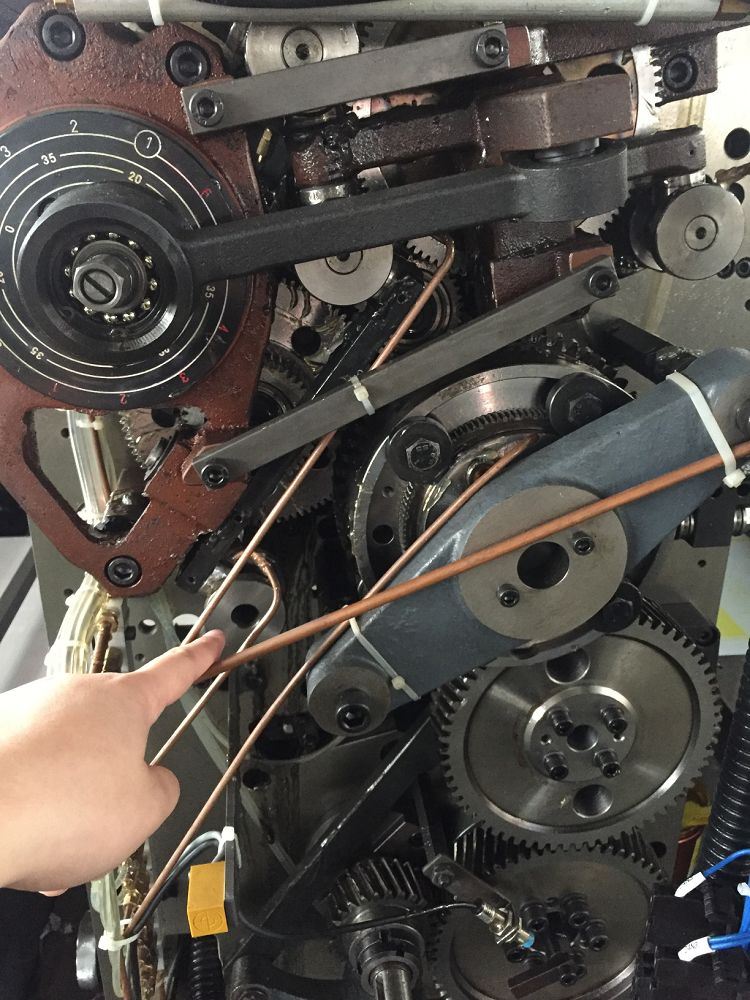

Automatic lubrication : Adopt drop lubrication ,every oil is one-time use;each lubrication point, the required amount of oil precise control, filling time to set the precise, to ensure that the equipment operating accuracy and life.