PS Plate Intermittent Offset Printing Machine for IML

Description

In today’s self-adhesive printing field, the share of traditional self-adhesive printing is gradually decreasing, and a variety of high-performance composite materials are gaining customers' pursuit, especially IML materials and IML printing machines.

ZONTEN ZTJ-330 offset IML printing machine was launched on the market in 2010 and has sold more than 800 equipment so far. It is the most trusted offset IMLprinting machine manufacturer in China.

Our company has a series of IMLprinting machine solutions that can be tailored to customer process requirements. Including bucket labels, chocolate labels, yogurt labels and so on. In northern China including Hebei and Shandong, a large number of loyal users use ZONTEN ZTJ-330 offset IML printing machine to print IML materials.

Technical Specification

| Model | ZTJ-330 | ZTJ-520 |

| Max. Web Width | 330mm | 520mm |

| Max. Printing Width | 320mm | 510mm |

| Printing Repeat | 100~350mm | 150~380mm |

| Thickness of Substrate | 0.1~0.3mm | 0.1~0.35mm |

| Machine Speed | 50-180rpm(50M/min) | 50~160rpm |

| Max. Unwind Diameter | 700mm | 1000mm |

| Max. Rewind Diameter | 700mm | 1000mm |

| Pneumatic Requirement | 7kg/cm² | 10kg/cm² |

| Total Capacrty | 30kw/6 colors(Not including UV) | 60kw/6 colors(Not including UV) |

| UV Capacity | 4.8kw/color | 7kw/color |

| Power | 3 Phases 380V | 3 Phases 380V |

| Overall Dimension(LxWx H) | 9500 x1700x1600mm | 11880x2110x1600mm |

| Machine Weight | about 13 ton/6 colors | about 15 ton/6 Colors |

More Details

The weight for each printing unit is 1500kgs.

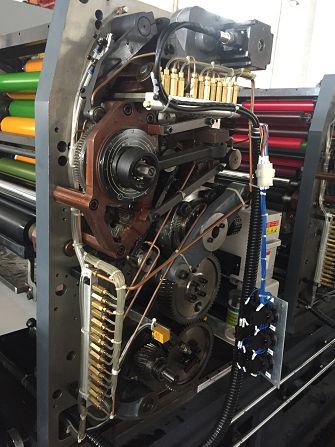

Using high-precision helical gears and fuselage panels made by Shanghai Electric's suppliers, including wall thickness 50mm, helical gear width 40mm, the maximum reduction of machine vibration and beating.

The whole machine adopts servo motor + helical gear (PS plate roller, blanket roller and embossing roller) + spur gear (uniform ink system) + stepping motor (ink fountain roller), no chain drive.

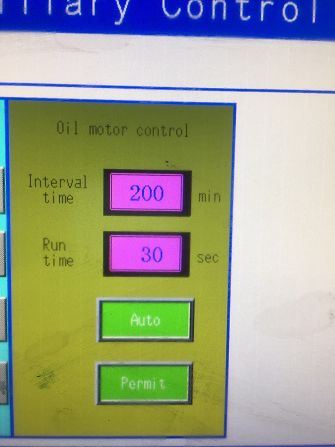

Automatic lubrication : Adopt drop lubrication ,every oil is one-time use;each lubrication point, the required amount of oil precise control, filling time to set the precise, to ensure that the equipment operating accuracy and life.

The movement control of the unit is controlled by a servo motor to ensure the accuracy of the movement.