PS Plate Offset Printing Machine

Description

After years of market recognition, Zhongte launched the 680 series of offset presses to meet the needs of customers in the packaging market.

From the earliest 330MM series to the latter 520 series, to the current 680 series, ZONTEN has spent 10 years to settle and realize the transformation from narrow-width labels to medium-width packaging, allowing customers to have a better printing process. more choices.

ZTJ-680 offset press has a paper feed width of 680MM, a printing width of 660MM, and a printing length of 400MM. The machine is controlled by a servo motor imported from Japan and driven by a British TRIO controller. It is a perfect choice for small carton packages.

In addition, in order to cooperate with customers from gravure to offset printing, ZTJ-680 Offset presses has developed "CHILL DRUM" to print film materials above 50 micron, which truly realizes the application of self-adhesive materials/coated paper materials/films. Full application of materials.

If you have any needs in this regard, please feel free to contact us.

Technical Specification

| Model | ZTJ-330 | ZTJ-520 |

| Max. Web Width | 330mm | 520mm |

| Max. Printing Width | 320mm | 510mm |

| Printing Repeat | 100~350mm | 150~380mm |

| Thickness of Substrate | 0.1~0.3mm | 0.1~0.35mm |

| Machine Speed | 50-180rpm(50M/min) | 50~160rpm |

| Max. Unwind Diameter | 700mm | 1000mm |

| Max. Rewind Diameter | 700mm | 1000mm |

| Pneumatic Requirement | 7kg/cm² | 10kg/cm² |

| Total Capacrty | 30kw/6 colors(Not including UV) | 60kw/6 colors(Not including UV) |

| UV Capacity | 4.8kw/color | 7kw/color |

| Power | 3 Phases 380V | 3 Phases 380V |

| Overall Dimension(LxWx H) | 9500 x1700x1600mm | 11880x2110x1600mm |

| Machine Weight | about 13 ton/6 colors | about 15 ton/6 Colors |

More Details

The weight for each printing unit is 1500kgs.

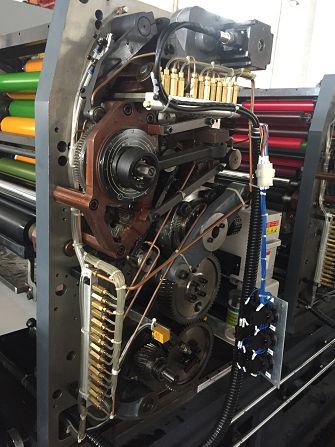

Using high-precision helical gears and fuselage panels made by Shanghai Electric's suppliers, including wall thickness 50mm, helical gear width 40mm, the maximum reduction of machine vibration and beating.

The whole machine adopts servo motor + helical gear (PS plate roller, blanket roller and embossing roller) + spur gear (uniform ink system) + stepping motor (ink fountain roller), no chain drive.

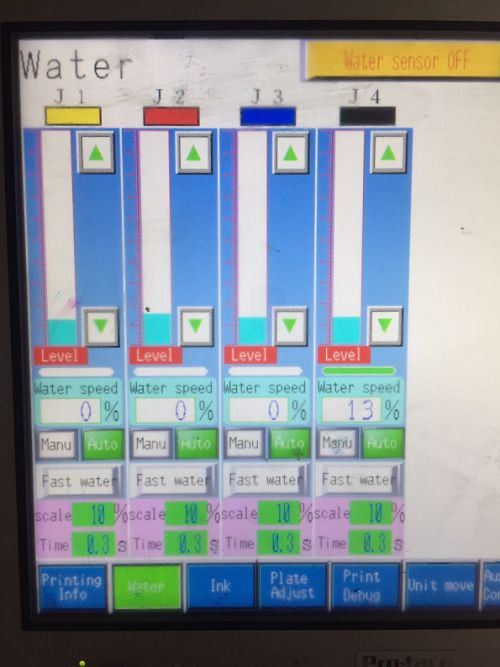

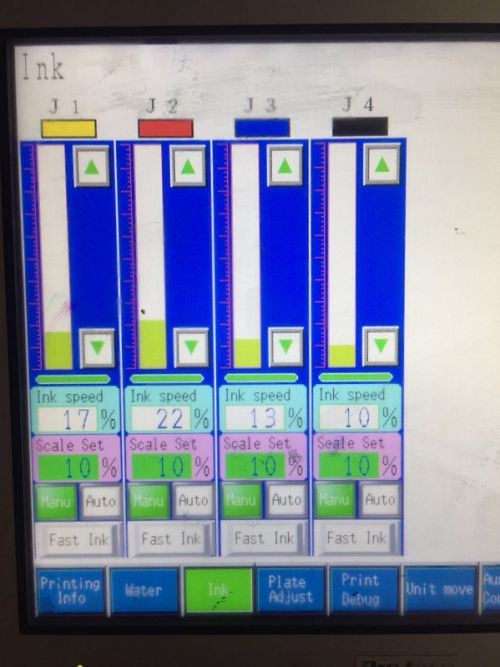

The rate of water &ink were controlled automatic ,it changed by different speed and also you can operate on touch screen.

Lineal adjustment :±5mm

Lateral adjustment :±2mm

Oblique adjustment: ± 0.12mm

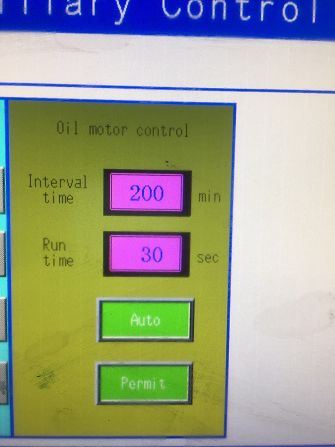

Automatic lubrication: Adopt drop lubrication ,every oil is one-time use;each lubrication point, the required amount of oil precise control, filling time to set the precise, to ensure that the equipment operating accuracy and life.

Europe standard electrical control box