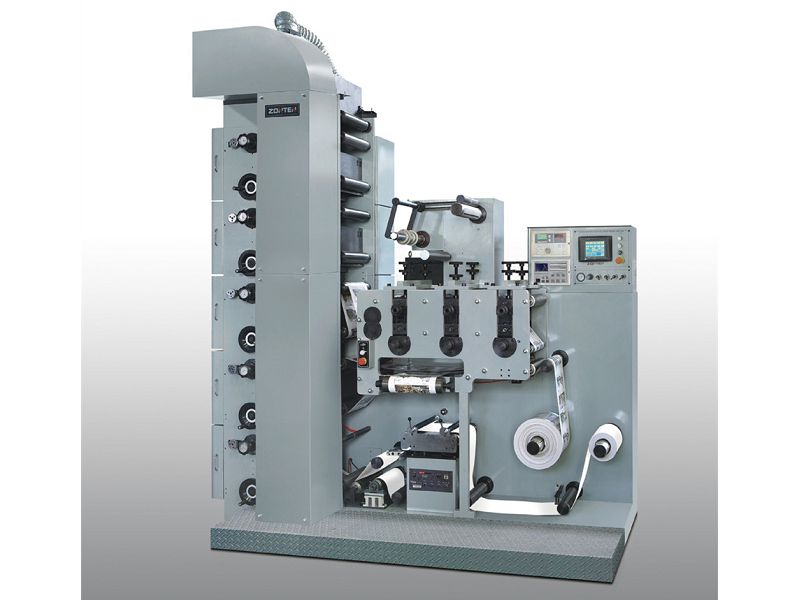

Shrink Sleeve Printing Machine

Description

SMART -680 shrink sleeve printing machine is a high-end combined film printing machine, which can carry out high-quality printing for various materials such as PVC/PET/BOPP/IML/aluminum foil.

Compared with traditional gravure printing machine, SMART -680 shrink sleeve printing machine has many advantages as follows:

1) The printing quality is more exquisite and the dots are more delicate. Traditional gravure printing machine adopts engraving roller and anilox roller. The highest screen line can only print 150 lines. The standard line of SMART-680 shrink sleeve printing machine is 225 lines, and the maximum line is 300

2) The cost of plate making is cheaper and the cycle is shorter. The traditional gravure printing mechanism is expensive, the cycle is 2 weeks, the shrink sleeve printing machine can be directly output from the CTP machine, and the cost of a plate is 10 yuan

3) Less ink consumption. Because the ink roller conducts ink injection, the ink usage rate of offset printing is even less.

4) The combination process is more abundant. Traditional gravure printing machine can perform printing function, shrink sleeve printing machine can realize combined printing of offset printing, flexo printing, gravure printing, silk screen, cold stamping, etc. It is more suitable for label and packaging industry.

Technical Specification

| Machine speed

Maximum print repeat length |

150M/ min 4-12color

635mm |

| Minimum print repeat length

Maximum paper width |

469.9mm

420mm |

| Minimum paper width

Maximum print width |

200mm (paper)、 300mm (film)

410mm |

| Substrate thickness

Unwinding the largest diameter |

0.04 -0.35mm

1000mm / 350Kg |

| Winding the largest diameter

Cold maximum income, unwinding diameter |

1000mm / 350Kg

600mm / 40Kg |

| Offset printing plate thickness

Flexographic printing plate thickness |

0.3mm

1.14mm |

| Blanket thickness

Servo motor power |

1.95mm

16.2kw |

| UV power

voltage |

6kw*6

3p 380V±10% |

| Control voltage

frequency |

220V

50Hz |

| Dimensions

Machine net weight |

16000×2400×2280/7color

Offset/flexo 2270Kg |

| Machine net weight

Machine net weight Machine net weight |

unwinding 1400Kg

Die cutter&waste collection 1350Kg rewinder 920Kg |

More Details

Moveable turn bar unit , support back side printing

Moveable cold foil unit , according to the different requirement of lables , cold foil unit can move to any position to complete the job.

Offset unit : Double route inking system with 21 roller inside , every unit has 9 separated servo driver controled and B&R system.

Flexo plate mounting machine and offset plate bending machine. It’s a Free supporting parts when customer buy the machine

Center control screen:

The machine parameters can be adjusted and shored at every work order by digital handles with also contain the machine best state in the printing time .the data cam isedd to setting machine state when the work order is stored and recalled , and achieve the control to whole machine include the basic function turning on ,turning off , speed adjustment , counting etc ....

Europe standard electrical box with CE safety certication