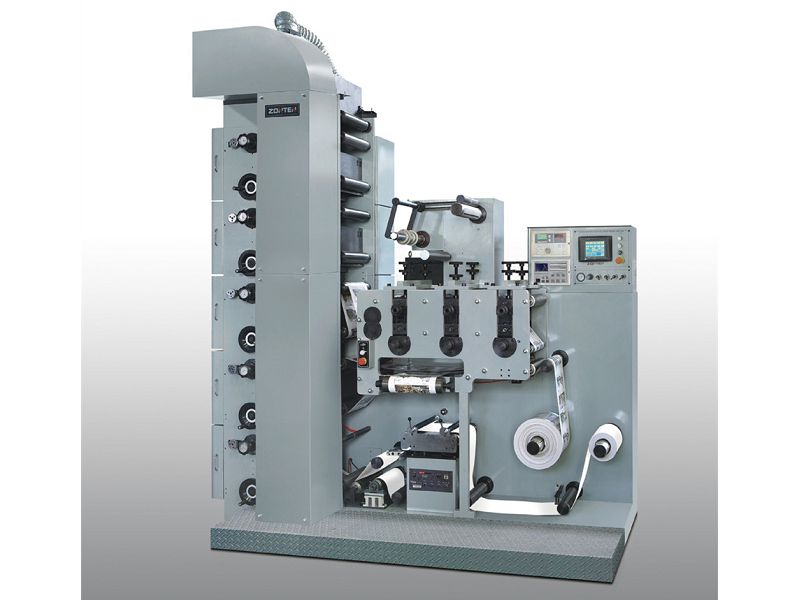

UV Intermittent Offset Printing Machine

Description

ZONTEN SMART uv offset printing machine currently has three widths of 420mm /560mm /680mm for customers to choose from. In the near future, 850mm 1000mm and 1300mm will be developed. The printing field will include labels/cartons/soft bags, etc.

In response to the government's energy saving and emission reduction policy, our company equipped the SMART uv offset printing machine with an LED UV dryer to ensure that it can reduce power and reduce polluting gas emissions before drying, which has been recognized and supported by many customers.

At the same time, we also provide many different brands of UV dryers for customers to choose from, and do our best to let customers get the most satisfactory UVoffset printing machine configuration in an effective budget.

If you want to know more detailed UV offset printing machine information, please contact us.

Technical Specification

| Machine speed

Maximum print repeat length |

150M/ min 4-12color

635mm |

| Minimum print repeat length

Maximum paper width |

469.9mm

420mm |

| Minimum paper width

Maximum print width |

200mm (paper)、 300mm (film)

410mm |

| Substrate thickness

Unwinding the largest diameter |

0.04 -0.35mm

1000mm / 350Kg |

| Winding the largest diameter

Cold maximum income, unwinding diameter |

1000mm / 350Kg

600mm / 40Kg |

| Offset printing plate thickness

Flexographic printing plate thickness |

0.3mm

1.14mm |

| Blanket thickness

Servo motor power |

1.95mm

16.2kw |

| UV power

voltage |

6kw*6

3p 380V±10% |

| Control voltage

frequency |

220V

50Hz |

| Dimensions

Machine net weight |

16000×2400×2280/7color

Offset/flexo 2270Kg |

| Machine net weight

Machine net weight Machine net weight |

unwinding 1400Kg

Die cutter&waste collection 1350Kg rewinder 920Kg |

More Details

Moveable cold foil unit , according to the different requirement of lables , cold foil unit can move to any position to complete the job.

Full Chilling drum system:

There’s 4 chilling roller on inking system , and one chilling drum before LED UV dryer to ensure the temperature of the material surface , so that it won’t be shirnkable . the minmium thickness material can reach 15 micron .

Basic 2 sets die cutting unit, support front and back side die cutter

Shaftless printing cylinder and blanket cylinder : using magnalium printing cylinder and blanket cylinder with double -pinch clamping technology for easily changing printing area nad printing method , convenience operator and low maintanance cost.

Options automatic unwinding exchange loading for clients when printing big roll job.

BST camera: Real-time monitoring of registration